Procesoptimalisatie

Slimmer inkopen, vlottere productie en betere ontwerpen

Een echte partner voor voorraadbeheer en oplossingen in de volledige waardeketen

Productiebedrijven

focussen

zich vaak op de grotere,

waardevolle onderdelen

bij het ontwerp en

vergeten de goedkopere onderdelen

, wat leidt tot

inefficiënties en onnodige kosten

in de waardeketen.

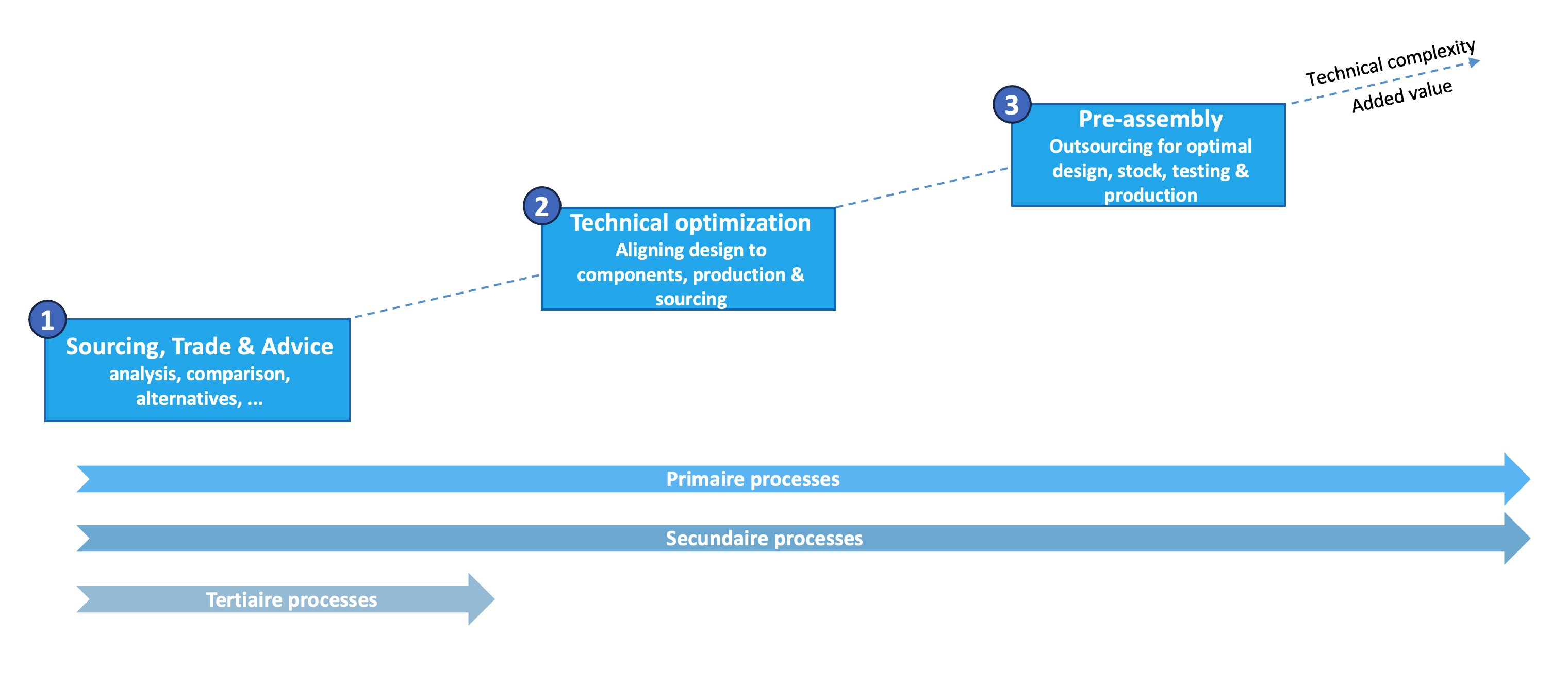

Bij Datkan kunnen we je helpen met verbeteringen in al deze stappen. Onze experts analyseren en adviseren over het

verbeteren van je sourcing

en bieden eveneens een volledige outsourcing en handel van bepaalde componenten.

We kunnen je

helpen je ontwerp technisch te optimaliseren

door het af te stemmen op de sourcing van componenten en de productie, waardoor kostbare en tijdrovende herontwerpen later in het proces worden verminderd.

Daarnaast kunnen we subassemblages leveren, volledig geassembleerd en getest , en deze just-in-time tijdens het productieproces aanleveren.

Onze oplossingen en diensten

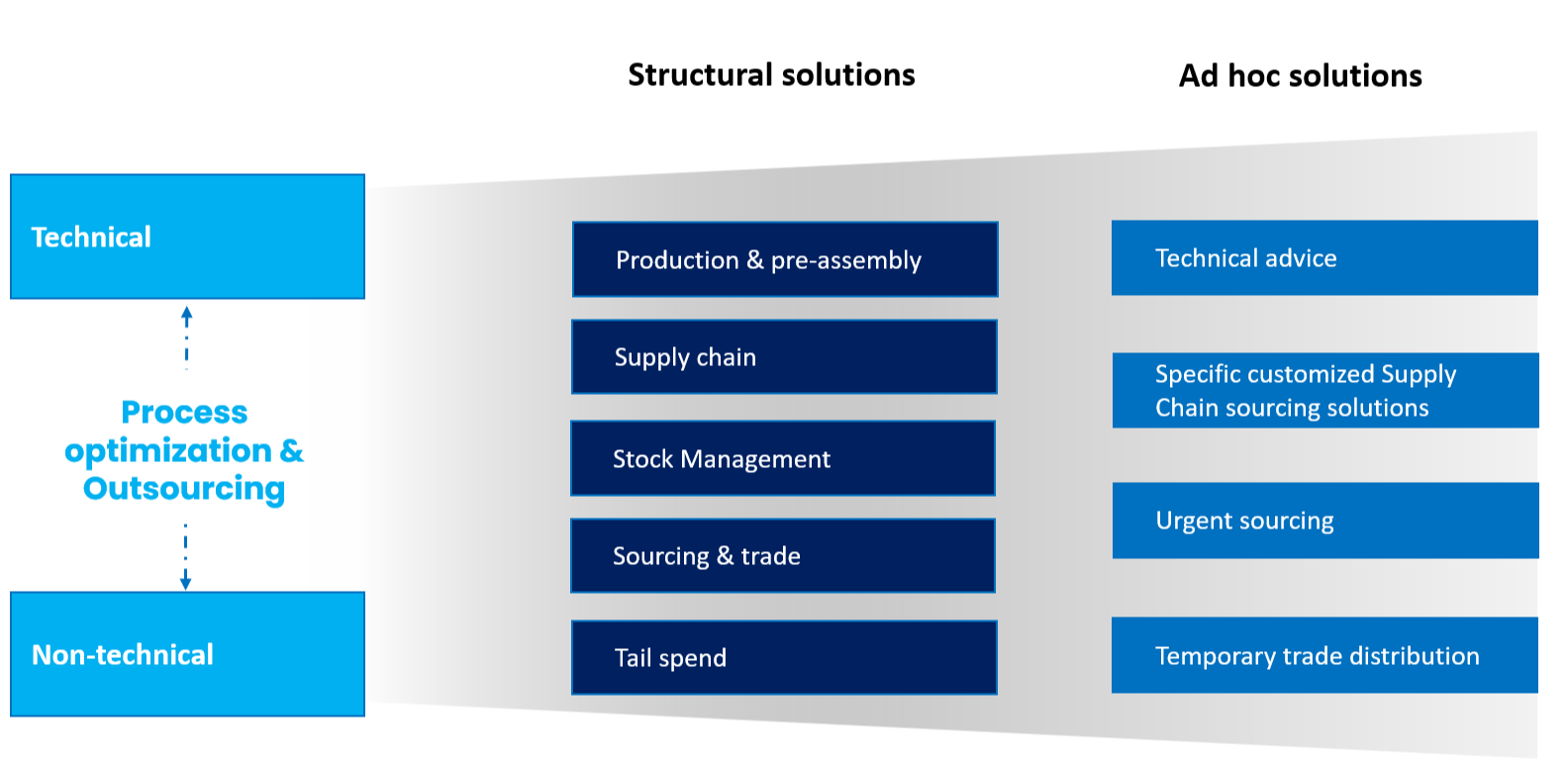

Onze oplossingen en diensten zijn gebaseerd op de belangrijkste stappen in de waardeketen. Ze zijn zowel technisch als niet-technisch van aard en kunnen structureel of ad-hoc worden aangeboden, afhankelijk van jouw behoeften.

We helpen minimaal met sourcing, handel, optimalisatie en voorraadbeheer van bepaalde componenten, en bieden tijdelijke distributieoplossingen indien nodig om continuïteit te waarborgen.

We bieden technisch advies om je componenten te optimaliseren en je ontwerp te verbeteren op basis van geoptimaliseerde sourcing, toeleveringsketen, testen en productie. Bij urgente situaties kunnen we de benodigde componenten voor je zoeken en leveren.

Je kunt ook jouw voorbereidende kitting en subassemblages aan ons uitbesteden, waarbij wij zorgdragen voor assemblage, testen en levering van op maat gemaakte oplossingen

.

Wie profiteert van onze oplossingen?

Onze positieve impact is zichtbaar in verschillende delen van de organisatie, waaronder sourcing en inkoop, engineering, productie en administratie.

Datkan is meer dan een leverancier

We voegen waarde toe.